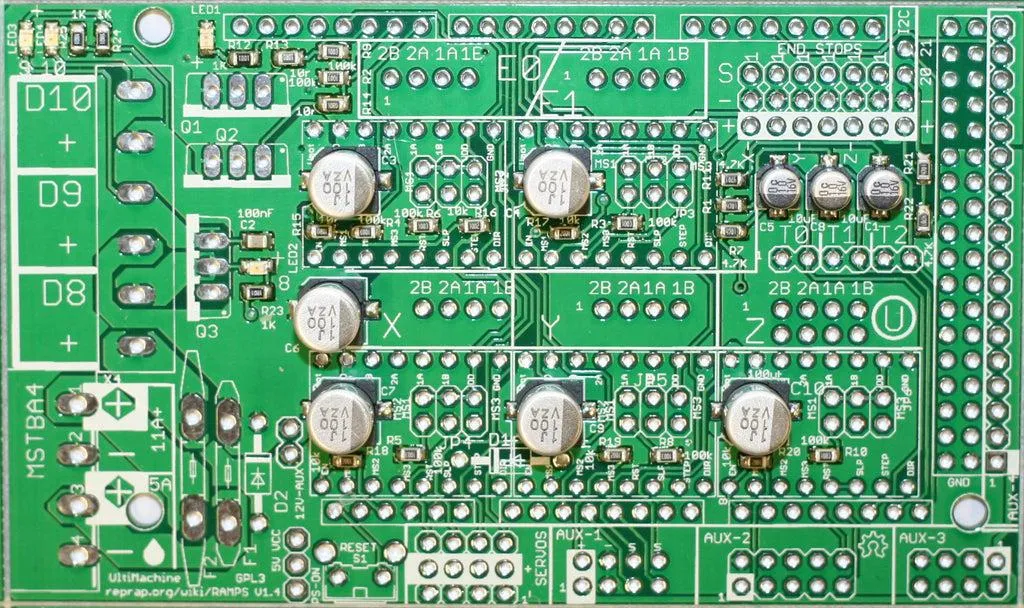

PCB ASSEMBLY INSPECTION AND TESTING

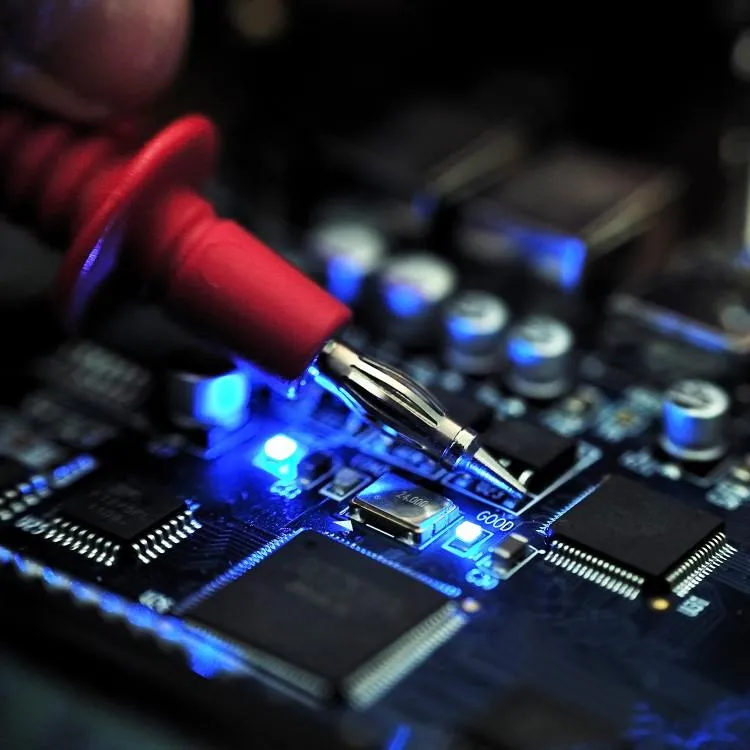

We inspect your printed circuit boards at various stages of the manufacturing/assembly process for early detection of faults. Correcting defects at an early stage improve yields during the PCB testing stage. We use visual inspection, automated optical inspection (AOI) and automated X-ray inspection. After the boards have been manufactured and have passed all the PCB assembly inspections they are ready for testing.

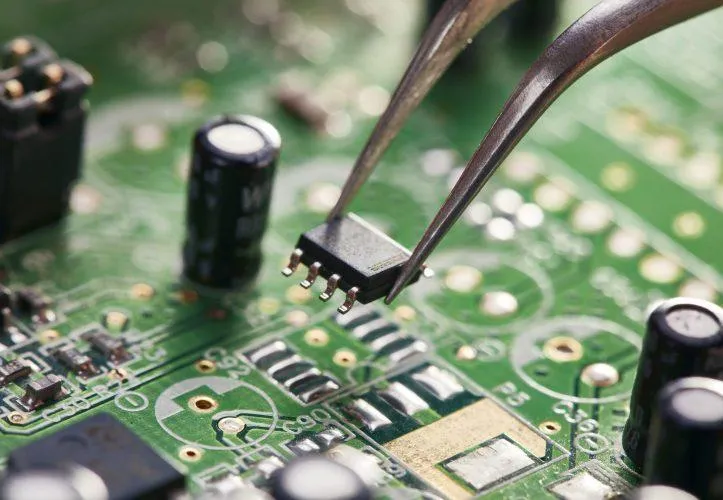

Common PCB assembly defects are

Open and short

Insufficient or excess solder

Missing components

Misaligned components

Wrong orientation

Defective components

PCB assembly testing is an integral part of our manufacturing process. There is a variety of PCB assembly testing methods. The most common ones are

In-Circuit Testing (ICT)

Flying Probe Testing

Burn-in Testing

Functional Testing

Benefits of Function Testing Include

By simulating the operating environment it eliminates the need for expensive PCB testing such ICT, flying probe and burn-in testing.

It helps detect and correct faults at various staging of manufacturing.

It helps to address potential issues early before going into final production, saving time and money.

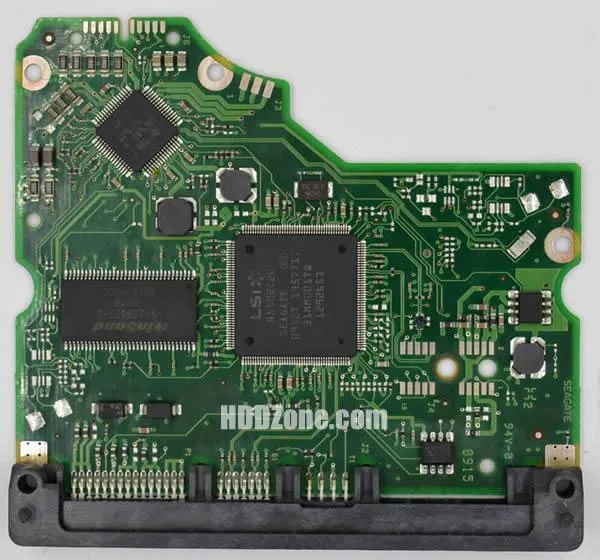

Prototyping

First stage of the PCB, proof of concept. Focused on functionality and demonstrable product. Board bring up and debug straight off the assembly line.

Shorts and open test on voltage rails

Basic confirmation of functionality & 'Board Bring Up

Basic power test supplies for stability and spec

Measure clocks & oscillators

Start test fixture (also known as jig) spec during this phase (You can provide your test fixture or we can develop one for you).

Rev A

Fix the first issues identified in Prototyping stage. Additional features check. Expand areas of test.

Program devices

Unblock functionality test

AC and DC measurement

Jitter & accuracy

Run diagnostics if available

Basic environmental tests

Test fixture development starts during this phase

Rev B

Expanded test procedures to include reliability testing at temperatures to accelerate life time testing Pilot Functional Testing.

Program devices

Unblock functionality test with some boards

AC and DC measurement with some boards

Jitter &accuracy with some boards

Run diagnostics with some boards

Test fixture development occurs during this phase

RAMP

Expanded test procedures to include reliability testing at temperatures to accelerate life time testing Pilot Functional Testing.

Program devices

Unblock functionality test with some boards

AC and DC measurement with some boards

Jitter & accuracy

Run diagnostics if available

Basic environmental tests

Test fixture development starts during this phase

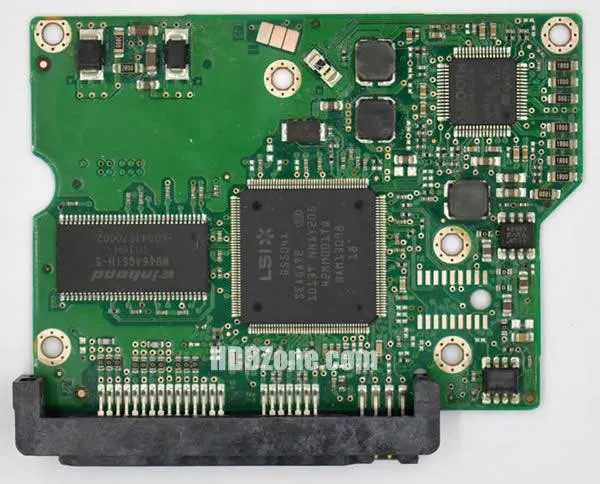

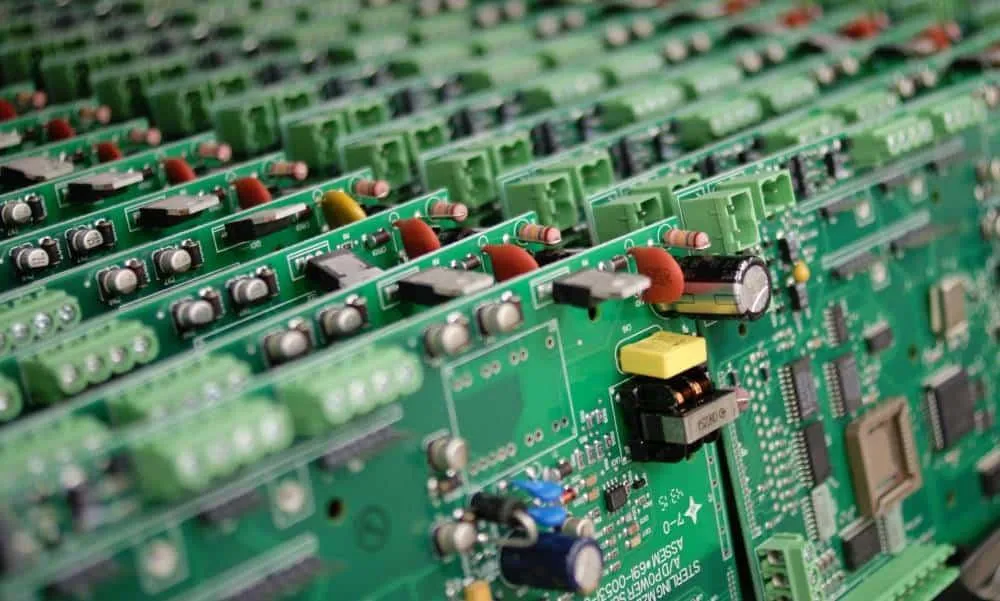

High Volume

Failure analysis is an ongoing process throughout which ensures continuous improvements and yield.

Start using test fixture

Run diagnostics jig randomly pull and test some boards

Run Functional Test

Our goal at Pacific EMS LLC is to achieve customer satisfaction with superior service and quality products. As your partner, communication is a vital element of a quality product and together we can determine the most effective solutions to meet your needs.